production

area.

of-the-art

technologies.

production.

it for you.

panel cutting

delivery dates.

processing.

Traditional craftsmen using robot-controlled cutting saws? We don’t see this as a contradiction because without state-of-the-art technology we wouldn’t be able to deliver the desired quality; meet deadlines or work cost-effectively. Whether panel cutting or CNC processing; for fittings, edging, surfaces or moulded parts, hi-tech solutions allow us to fulfil our and our customers’ wishes in the corresponding quality.

Are you familiar with Homag’s HPS 320 FlexTec panel cutting machine? Or HOMAG Automation’s intelligent panel store? Used in combination with highly rationalized robot feeding systems this equipment has enabled us to achieve a technological quantum leap. Thanks to these two hi-tech machines we are able to provide both – single-unit batches and high-volume quantities. Exactly what is required to meet both individual wishes and to react quickly to peaks in demand.

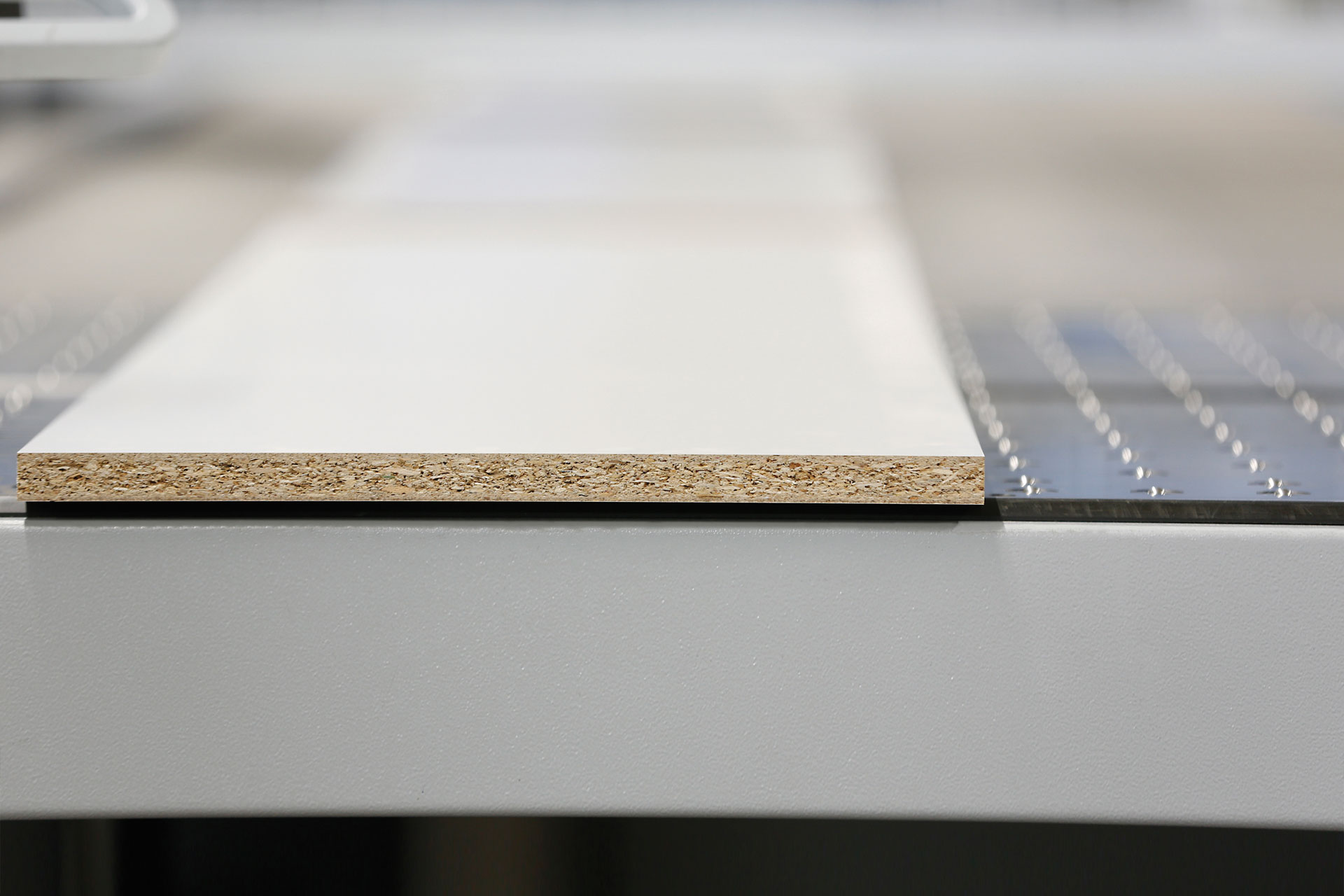

Equipped with these systems we process around 1 500 m² of panel material each day; are able to cut single panels and to handle cutting lengths up to 3 200 mm. Optimization software allows us to carry out fully automated creation of cutting patterns; stack cutting up to 100 mm is possible.

From line drilling to 5-axis machining, our eight CNC-controlled processing centres allow us to realize any conceivable construction. Do you need to edge or re-work moulded parts? Also not a problem. Workpieces can be up to 6000 x 2000 mm in size; the maximum processing height is 600 mm and it goes without saying that insertion and feeding are carried out automatically.

Our range includes products from all leading manufacturers of fittings. Your advantage? A genuinely unrestricted choice which allows us to use exactly the components which you and your customers want.

Can you achieve a zero joint? Can you achieve maximum angle accuracy? We can answer both of these questions with an unambiguous “Yes”. Thanks to our KAL 526 double-sided edge banding machine we are able to execute small and medium serial production runs with any fabricated workpiece. In addition to this highly rationalized edge banding technology we also have highly precise robot handling systems – the KUKA KR 180 R3300 PA jointed-arm robot with a payload of 180 kg and a reach of 3200 mm carries out palletizing tasks around the double-sided edge banding machine.

Edges up to 60 mm in width can be fed at rates of 20 m/min using laser technology; the feed rate for edges up to 20 mm is approx. 25 m/min.

Dust-free surfaces? A wide range of paint finishes? Our modern surface production area allows us to meet virtually all your requirements. And it goes without saying that we can also apply films cut to size.

No matter how challenging your requirements are, our three membrane presses can work flat out to meet them. Two cold and one hot press allow us to produce moulded parts up to 3000 mm in length and to process wood, plastics and acrylics.

Sometimes time is at a premium. You’re still working on an order and the next customer is already waiting for his furniture to be delivered.

Why not take advantage of our ready-made furniture service to handle such situations? We can manufacture and assemble your furniture before delivering it and all the required fittings to wherever you need them.

Your order has been completed – what now? You can rely on us not only to deliver your furniture to you on time but also to pack it so well that it arrives in excellent condition. Modern cardboard cutting machines allow us to pack each piece of furniture individually, guaranteeing that nothing can go wrong. After all, we are experts in this field, dispatching 50 articulated lorries loaded with furniture to customers every week.